- Home

- Products

- Gallery

- About Us

- Custom Service

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Easy Publish Time: 2023-12-27 Origin: Site

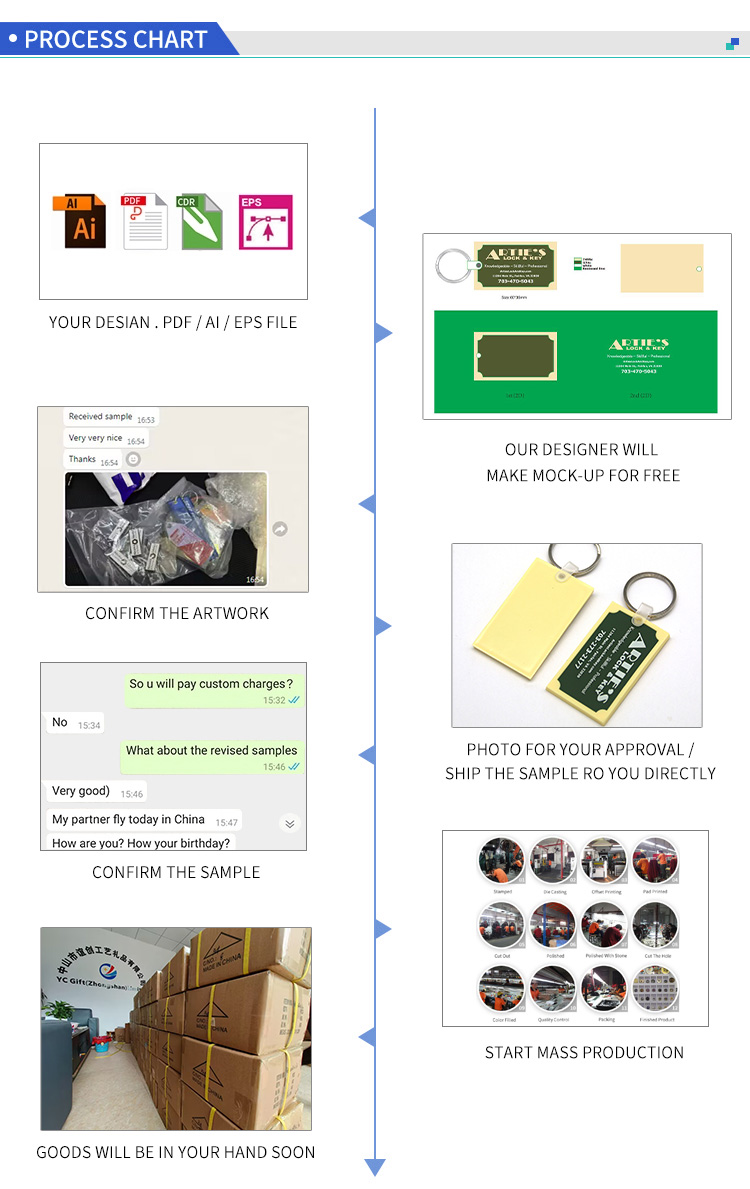

PVC keychains have become popular accessories, combining functionality with personalized design. Let's take a behind-the-scenes look at the production process of PVC keychains, from concept to the final product.

- *Creative Vision:* The production journey begins with a design concept. Whether it's a company logo, a character, or a custom shape, the keychain's design is the foundation of the entire process.

- *Digital Precision:* Skilled graphic designers transform the concept into digital artwork. This stage involves choosing colors, defining details, and ensuring the design is compatible with the PVC material.

- *Precision Molding:* The digital artwork guides the creation of a mold. This mold will determine the shape and details of the PVC keychain. Molds can be crafted for single-color or multi-color designs.

- *Colorful Choices:* PVC material comes in various colors. The chosen colors are precisely mixed to match the design specifications. The material is then prepared for the injection molding process.

- *Forming the Foundation:* The prepared PVC material is injected into the mold. This process ensures that the keychain takes on the desired shape and captures the intricate details of the design.

- *Solidification:* After injection, the PVC material needs time to cool and set. This stage is crucial for the keychain to maintain its shape and durability. The cooling time varies depending on the design complexity.

- *Precision Crafting:* Once the PVC material has set, the keychains are carefully cut and trimmed to remove excess material. This step ensures the final product meets the exact specifications of the design.

- *Functional Addition:* A keyring attachment is added to the keychain during production. This can be a simple metal ring or a more customized attachment, depending on the design and intended use.

- *Thorough Examination:* Every PVC keychain undergoes a quality inspection. Skilled inspectors examine each keychain for consistency in color, shape, and overall quality. Any imperfections are addressed before the final product is approved.

- *Ready for Distribution:* The finalized PVC keychains are carefully packaged, ready to be distributed or sold. Packaging may include branding elements, product information, or customization options for bulk orders.

- *Global Distribution:* The PVC keychains are then shipped to their final destination. Whether they're promotional items, retail products, or personalized gifts, these keychains are ready to make their way into the hands of end-users.

At YC Gifts, we take pride in the precision and craftsmanship of our PVC keychains. From concept to production, each keychain is a testament to our commitment to quality and customization. Whether you're looking for branded promotional items or unique personal accessories, trust YC Gifts to bring your PVC keychain vision to life.

| | Address: 9th Floor, Building A, No. 3, North Industrial Avenue, Xiaolan Town, Zhongshan, Guangdong, China |

| | Custom Support & Sale: +86 18676423573 |

| | Working Time: Mon–Sat: 08:00–18:00 |

| | E-mail: anita@ycgifts.com |